UL2854

High Temperature Silicone Wire uses tinned copper or bare copper conductors, and has the characteristics of high temperature resistance, strong flexibility, corrosion resistance, and flame retardancy. It is suitable for industrial, electronic, automotive and home appliance fields. It supports customized specifications and complies with standards such as UL 2854, with a temperature resistance of -60℃ to +200℃. Compared with PVC wires, silicone wires are more resistant to high temperatures and aging, and are suitable for high-demand environments.

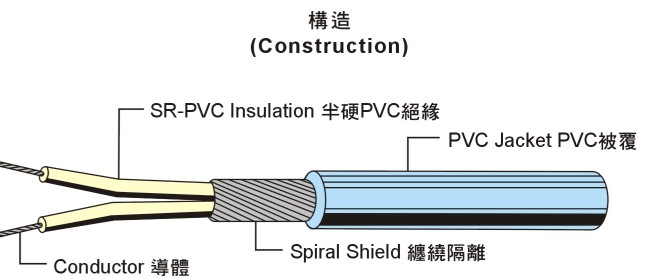

UL 2854 Multi-Core Shielded Wire

■ PRODUCT DESCRIPTION

● Tinned or bare,stranded or solid copper conductor,30-18 AWG.

● Color-coded PVC insulation similar to UL1061.

● Tinned or bare copper wire spiral shield.

● PVC jacket.

● Rated temperature:80℃. Rated voltage:30 volts.

● Passes UL VW - 1SC vertical flame test.

● Reference standard:UL subject 758,UL 1581.

■ APPLICATIONS

● For use in recording studios,sound systems and electronic circuits.

CABLE CONSTRUCTION: | ||||||

Conductor | Insulation | Spiral | Jacket | Overall | No. | |

AWG | No./mm | mm | N o./m m | mm | mm | |

30 | 7/0.102 | 0.26 | 41/0.10 | 0.35 | 2.40 | 2-cores |

28 | 7/0.127 | 46/0.10 | 0.43 | 2.85 | ||

26 | 7/0.16 | 45/0.12 | 0.43 | 3.10 | ||

24 | 11/0.16 | 62/0.10 | 0.35 | 3.15 | ||

22 | 17/0.16 | 62/0.12 | 0.35 | 3.50 | ||

20 | 26/0.16 | 72/0.12 | 0.35 | 3.86 | ||

18 | 41/0.16 | 82/0.12 | 0.35 | 4.34 | ||

30 | 7/0.102 | 0.26 | 46/0.10 | 0.37 | 2.55 | 3-cores |

28 | 7/0.127 | 53/0. 10 | 0.44 | 3.10 | ||

26 | 7/0.16 | 62/0. 10 | 0.35 | 3.10 | ||

24 | 11/0.16 | 69/0. 10 | 0.35 | 3.32 | ||

22 | 17/0.16 | 72/0. 12 | 0.35 | 3.70 | ||

20 | 26/0.16 | 82/0. 12 | 0.35 | 4.08 | ||

18 | 41/0.16 | 96/0. 12 | 0.35 | 4.60 | ||

28 | 7/0.127 | 0.26 | 56/0. 12 | 0.44 | 3.30 | 4-cores |

26 | 7/0.16 | 63/0. 12 | 0.42 | 3.50 | ||

Features of High Temperature Silicone Wire

High temperature resistance: It can work normally in extremely high temperature environment and is not easy to melt or deform.

Strong flexibility: Compared with PVC or other materials, silicone wire is softer and easier to install and wire.

Excellent electrical performance: Low resistance and high conductivity ensure stable current transmission.

Corrosion resistance: Silicone material has strong tolerance to chemicals, oil, moisture, etc.

Flame retardancy: Most models can pass the UL VW-1 flame retardant test and meet safety standards.

Advantages of High Temperature Silicone Wire

Wide operating temperature range: Suitable for high and low temperature environments and can withstand extreme temperature changes.

Long service life: Silicone material is resistant to aging and can maintain stable performance even in harsh environments.

Environmentally friendly and non-toxic: It complies with RoHS standards and does not contain harmful substances. It is suitable for occasions with high environmental requirements.

High safety: It has good heat resistance, voltage resistance and fire resistance, reducing the risk of short circuit or wire aging.

Scope of use of High Temperature Silicone Wire

Industrial application: used in motors, heating equipment, aerospace and other fields in high temperature working environments.

Electronic equipment: suitable for power cords, connecting wires, sensor cables, medical equipment, etc.

Automotive industry: used in high temperature parts such as wiring harnesses in engine compartments, battery connecting wires, etc.

Household appliances: such as internal wiring of heat-resistant appliances such as ovens, rice cookers, and water heaters.

Is customization supported?

Wire gauge optional (30-18 AWG)

Color customizable

Conductor type optional (tinned copper, bare copper, stranded or solid)

Shielding layer optional (tinned copper braided shield or no shield)

Length customizable

FAQ

Q1: What is the temperature range of High Temperature Silicone Wire?

A1: The specific temperature range depends on the model. Generally, it can withstand high temperature environments from -60℃ to +200℃, and some models can reach 250℃.

Q2: Is the wire UL certified?

A2: Yes, some models meet UL standards, such as UL 2854 (for multi-core shielded wires), and meet UL 758, UL 1581 and other specifications.

Q3: Is this wire suitable for outdoor environments?

A3: The silicone material itself has strong weather resistance, but if it is exposed to UV rays for a long time, it is recommended to choose a model with a special protective layer.

Q4: Is High Temperature Silicone Wire waterproof?

A4: The silicone material itself has a certain waterproof ability, but whether it is completely waterproof depends on the design of the cable, such as whether there is an additional waterproof coating or sealing treatment.

Q5: How to store this wire to extend its service life?

A5: When storing, avoid direct sunlight and humid environments. It is best to store it in a dry and ventilated environment and avoid contact with oil or corrosive chemicals.

Q6: What are the advantages of High Temperature Silicone Wire over PVC wire?

A6: Silicone wire has higher temperature resistance, better flexibility, and stronger aging resistance, while PVC wire is cheaper but has poorer temperature resistance.

Q7: Can this wire be used for audio and studio equipment?

A7: Yes, UL 2854 multi-core shielded wire is suitable for studios, sound systems and electronic circuits, and can effectively reduce electromagnetic interference.

If you need more information or customization requirements, please feel free to contact us!

Specializing in the production of wire and cable Hong Kong funded enterprises (both domestic and foreign sales); has won the IS09001-2000 international quality certification and the United States UL safety certification, is a professional wire manufacturers.

Tel: +86-769-8178 1133

Mobile: +86-13549233111

E-mail: andy@herwell.com.cn

Add: No.13 Shui Chang Er Road, Shui Kou Village, Dalang Town, Dongguan City, Guangdong Province, China