UL1617 UL1618

VC Reinforced Electrical Wire is a high-performance cable with tinned or bare copper conductors and PVC insulation and outer jacket. It has high temperature resistance and high voltage withstand capability and is widely used for internal wiring of electronic and electrical equipment to ensure reliable power transmission and signal connection.

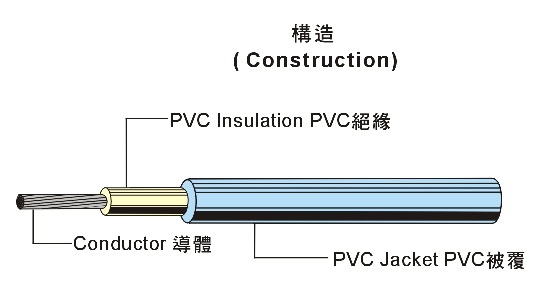

■PRODUCT DESCRIPTION:

●Stranded of solid,tinned or bare copper conductor.

●Color-coded PVC insulation and PVC jacket.

●Rated UL 1617:105℃,600 volts. UL 1618:80℃,300 Volts.

●Uniform thickness of wire to ensure easy stripping and cutting.

●Passes UL VW-1 vertical flame test.

●Jacket thickness:from 5 to 40 mils (0.127 to 1.016mm).

●Reference standard:UL subject 758,UL 1581.

■APPLICATIONS:

●Internal wiring of electronic and electrical equipment.

CABLE CONSTRUCTION | ||||||

UL | Conductor | Insulation | Jacket | OveralI | ||

AWG | No./mm | mm | mm | mm | mm | |

UL 1617 | 26 | 7/0.16 | 0.48 | 0.79 | 0.40 | 2.90 |

24 | 11/0.16 | 0.61 | 3.00 | |||

22 | 17/0.16 | 0.76 | 3.20 | |||

20 | 26/0.16 | 0.94 | 3.40 | |||

18 | 16/0.254 | 1.16 | 3.60 | |||

16 | 26/0.254 | 1.49 | 3.90 | |||

14 | 41 /0.254 | 1.88 | 4.30 | |||

12 | 65/0.254 | 2.37 | 4.80 | |||

10 | 105/0.254 | 3.01 | 5.80 | |||

UL 1618 | 26 | 7/0.16 | 0.48 | 0.40 | 0.41 | 2.10 |

24 | 11/0.16 | 0.61 | 2.20 | |||

22 | 17/0.16 | 0.76 | 2.40 | |||

20 | 26/0.16 | 0.94 | 2.60 | |||

18 | 16/0.254 | 1.16 | 2.90 | |||

16 | 26/0.254 | 1.49 | 3.30 | |||

14 | 41/0.254 | 1.88 | 3.50 | |||

12 | 65/0.254 | 2.37 | 4.00 | |||

10 | 105/0.254 | 3.01 | 5.10 | |||

Features:

Conductor material: Optional tinned or bare copper conductors provide excellent conductivity.

Insulation material: Color-coded PVC insulation layer for easy identification and installation.

Rated temperature and voltage:

UL 1617: 105℃ temperature resistance, 600V rated voltage;

UL 1618: 80℃ temperature resistance, 300V rated voltage.

Uniform cable thickness: Easy to strip and cut, improve installation efficiency.

Passed UL VW-1 fire test: Provides higher fire safety.

Sheath thickness: 5 to 40 mils (0.127 to 1.016 mm) to meet different protection needs.

Reference standards: Comply with UL 758 and UL 1581 standards to ensure product quality and safety.

Advantages:

High safety: Passed UL VW-1 vertical flame test, with strong fire resistance, ensuring safe use.

High temperature resistance: 105℃ temperature resistance, adapt to work needs in high temperature environment.

Excellent abrasion resistance: The PVC outer sheath provides strong resistance to aging and corrosion, extending the service life of the cable.

Easy to install: Uniform insulation thickness and color-coded design simplify the installation and maintenance process.

Scope of use:

Electronic equipment: Mainly used for internal electrical connections of electronic equipment, such as computers, TVs, stereos, etc.

Electrical equipment: Used for wiring of electrical equipment such as home appliances and tools, providing reliable power and signal transmission.

Automation equipment: Used for cable wiring of industrial automation equipment and control systems.

Support customization:

Yes, we support customization of PVC reinforced electrical cables according to customer needs, including wire length, conductor type, sheath color, sheath thickness, etc.

FAQ:

Q1: What should I do when the cable has unstable power transmission?

A1: Please check whether the cable connection is loose, whether the conductor is damaged or oxidized, whether the outer layer of the cable is worn, and replace the cable if necessary.

Q2: How to ensure that the cable can adapt to high temperature environment?

A2: This product supports a temperature resistance design of 105℃ and is suitable for use in high temperature environments. Please confirm that your working environment meets this temperature requirement.

Q3: Does the cable require regular maintenance?

A3: The cable should be kept away from long-term exposure to high temperature, humidity or corrosive chemicals. Regularly check the integrity of the insulation layer and sheath to ensure that the cable is not damaged.

Q4: What should I do if the cable short-circuits?

A4: Immediately cut off the power supply and check whether the cable connector and outer sheath are damaged. If damaged parts are found, the cable should be replaced as soon as possible.

Q5: How can I confirm that the cable meets the requirements of my equipment?

A5: Please check whether the rated voltage, temperature resistance range, standard, etc. of the cable meet the requirements of your equipment, or contact us for technical consultation and customization services.

PVC reinforced electrical cables provide stable and safe power and signal connections for your electronic and electrical equipment, suitable for a variety of working environments, and ensure efficient operation of the equipment.

Specializing in the production of wire and cable Hong Kong funded enterprises (both domestic and foreign sales); has won the IS09001-2000 international quality certification and the United States UL safety certification, is a professional wire manufacturers.

Tel: +86-769-8178 1133

Mobile: +86-13549233111

E-mail: andy@herwell.com.cn

Add: No.13 Shui Chang Er Road, Shui Kou Village, Dalang Town, Dongguan City, Guangdong Province, China